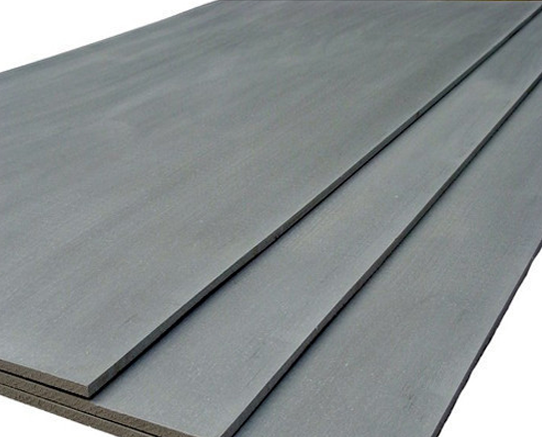

Fiber Cement Boards

DESCRIPTION

- Since 1900s by Ludwig Hatscheck

- Produced by 43 Companies, 48% of Cement Board Producers.

- Consists of Cement, Water, Silica, Limestone flour and Fibers; recycled, synthetic and cellulose pulp.

- Alternate additives – Chemicals that produce coagulation

Properties

- Durable Impact resistant

- Resistant to Moisture Decay

- Can be printed, wall papered, painted, cut, carved

- Relatively easy to handle due to low weight

- Size : 1220 x 2440 mm

- Thickness : 4 – 18 MM

- Size : 1200 x 2400 mm

- Thickness : 4 – 18 MM

Applications

- Roofing, Shingles, Shales

- Exterior and Partition Walls

- Flooring, Tile backing

- Prefabricated houses

- Facade, Waterboard and backing.

Advantages

- Savings in Cost, space, Time, Convenience

- Environment Friendly

- Highly Durable, Impact Resistant

- Resistant to Fire, Water, termites, Fungus, Weather

Disadvantages

- High Initial cost compared to Gypsum Board

- Heavier than Gypsum board, so expensive

- Awkward to handle and transport.