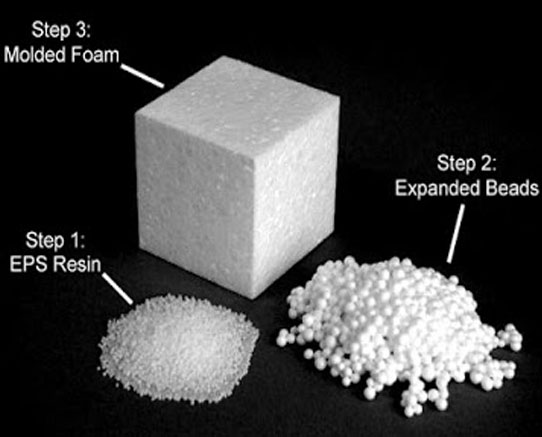

Expanded Polystyrene (EPS)

DESCRIPTION

EPS is a foam plastic material produced from solid beads of Polystyrene. It is a closed cell, rigid foam material produced from Styrene, which forms the cellular structure. Expanded Polystyrene is commonly moulded vacuum packed/ formed

PROPERTIES

- Uses: Industrial/food Packaging, as light weight filling/insulation in construction fields, Art and vent management stages/ decorative models etc..

- Advantages: Easy to install, Cost effective, Reduced Energy Consumption / Recycled Content / Localized Distribution / Improved Indoor Air Quality.

- Sizes: 1 to 6 M x 1.25/1 M x 10 to 1250 MM

- Density: 10 to 50 kgs/m3

Extruded Polystyrene (XPS)

DESCRIPTION

Extruded Polystyrene (XPS) insulation is manufactured using a process of extrusion. This continuous process results in a closed cell structure with a smooth skin on the top and bottom of the board. The closed cell structure of extruded polystyrene (XPS) prevents water penetration to the structure of the insulation board and provides long term strength and durability.

PROPERTIES

- Uses: Most commonly used for construction application as insulation, and as light weight floor filling in landscaping/construction/industrial projects.

- Advantages: Less water absorption, Better Thermal conductivity, Greater compressive strength, Reduced Energy Consumption.

- Sizes: 2500/1250 x 600 x 25 -100 MM

- Density: 30-50 Kgs/M3.